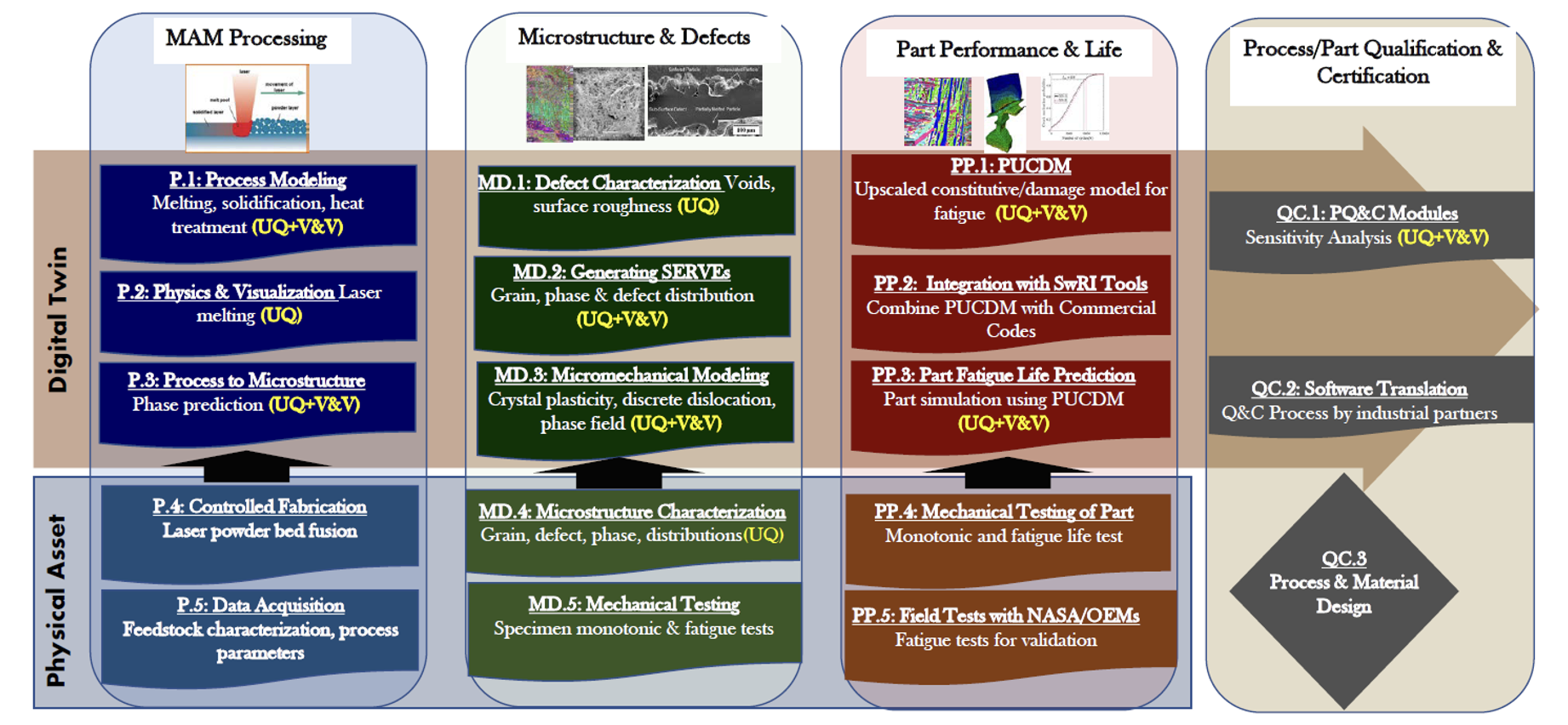

IMQCAM institute organization and structure

To accomplish the stated goals, the Institute has been organized into three enclaves:

Process modeling

The first enclave, led by Prof. Tony Rollett (CMU), coordinates thrusts for feedstock, printing of test articles (mainly fatigue samples), defect characterization & modeling, microstructure characterization and modeling, phase modeling, and strength modeling.

Multiscale modeling of properties, performance & life

The second enclave, led by Prof. Somnath Ghosh (JHU), incorporates micromechanics and multiscale modeling, physics-based coarse-grained simulations of plasticity and fatigue, fatigue life prediction from physics-based short crack models, Machine Learning, UQ/V&V in micromechanical & upscaled models, sensitivity analysis, HYPAD & UQ, fatigue experiments & characterization for validating micromechanical/upscaled models, microstructure and defect characterization for calibrating & validating models, and location-specific property, microstructure & process design.

Digital twin-assisted qualification & certification

The third enclave, led by Brendan Croom (JHU-APL) and Prof. Sankaran Mahadevan (Vanderbilt), coordinates and integrates outputs from enclaves 1 and 2 with part certification requirements. It uses the validated predictions of fatigue to assist the engineer in getting an AM part certified using maximal DT use and minimal experimental data. The Q&C team has reviewed internal NASA-STD-6030 qualification protocols to identify opportunities for digital twin models to address limiting assumptions, obstacles, and other challenges with qualifying AM hardware.